|

Sanwei (Hong Kong) Co., Ltd.

|

hot sales Black-white adhesive tape/adhesive die cutting

| Price: | 0.03 USD |

| Payment Terms: | T/T |

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Black & white

Shading

Good visible light wavelength range of 400 to 700rm

The thickness of tape

65um

Light transmittance

0.006%

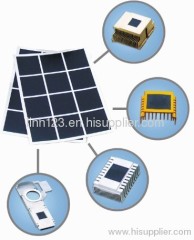

Black and white glue, which belongs to one kind of shading tape, mainly usedto paste the shading effect of optical display device, the material is PET, twocoating into. The amount of coating 20.13/19.56, initial stress 1/1 (GB 4852),black adhesion >1.79KG/IN (GB/T 2792), retention of >20H (GB 4851),peeling strength of 6 (90 ° peeling method), black shading rate of >99.9%,white reflectivity of >88, temperature of -10-100 ℃, the tensile strength of the 200-270 newton;

Has the advantages of moisture resistance, anti ultraviolet radiation and shading effect is good, but also moderate viscosity, tear no residue after removal of P65BW and X653-2, black and white glue is widely used innotebook computer. Mobile phone.PDA. digital display component backlightframe is fixed and shading effect, mainly used for mobile phone backlight,GPS backlight and other electronic display manufacturing industry.

P65BW and X653-2 were black and white glue is a double shading glue, whiteglue thickness is 0.065MM, the material is PET, flour adhesive >1.9KG/IN,black >1.7KG/IN >20H adhesion, retention, shading rate of >99.9%, reflectivity of >86%, temperature of -10-100 ℃, the tensile strength of 200-270 Newton;X653-2 black and white glue in the release degree PET film, cutting and rotarycutting has good processing performance, not easy in high temperature andhigh speed operation fragment. No glue overflow phenomenon. P65BW and X653-2 black and white glue has the following characteristics:

► thickness is very accurate, and the whole material thickness is very uniform.

► processing good, can cut to precise cutting shape, can also be usedmanually by adhesive bonding

► cutting high strength

► mainly for affixed to the product source side or product side sticking cloth,mainly cover and light reflecting effect

P65BW and X653-2 black and white glue is widely used in notebook computer.Mobile phone. PDA. digital display component backlight frame is fixed and the shading effect.

1 technical data sheet

Fifth revision date: 2011/12/01

Product Description: P65BW and X653-2 is a use of a special process to produce black and white film, double-sided tape to the substrate, compositesubstrate and a special black and white PET, integrated performance is very excellent, with shading and reflectance function, white face almost does not absorb light, black shading effect is good, no needle point light, suitable for fixed LCD and backlight.

Material properties (not as a standard objective)

The material that

The common physical characteristics

The type of glue

Acrylic acid

The steel adhesion (stripping)

Black: 15.5N/25mm

White: 18.5N/25mm

GB/T2792 1998

Base material

Transparent PET

Static shear force (keep)

1000g, 6.4cm²,

1400min+;

Thickness

65µ m

GB/T4851 1998

From the type material

25µ m+75µ m

The initial adhesion (Chu Nian)

≥ 100mm

Total

165µ m

GB/T4852 2002 slope method

White Reflectance

88%

Black shading rate

99.9%

From the type material

Transparent PET/ transparent PET

Solvent resistance

Good

Colors

The White / black surface

Temperature tolerance

100 ℃

Period of validity

From the delivery date of 12 months, at 21 ℃ (70 ° F) and 50% relative humidity environment preservation

The product structure

Transparent PET film

Acrylic adhesive

A special black and white PET substrate

Transparent PET film

Suitable for use

LCD and backlight module fixed. For light, backlight LCD fixed.

Dimensions

The thickness of tape (µ m)

Width (mm)

Length (m)

65

1020

50

Note: we can accept other dimensions (width, extra length), please contactus.

Product description

P65BW and X653-2 black and white film tape

Application skills

The 1 bonding strength depends on the

2 in order to get the best stick 3 ideal application temperature range

The bonding surface

Force, bonding surfaces must be

Around 21 ℃ , 38 ℃

Glue operation stability

Should be clean, dry and all

(70 ° F ° F; 100)

Solid pressure can

Uniform and flat. The typical cleaning

The initial use of adhesive

High adhesive contact

Solvent of isopropanol and

With the paste surface, not

Performance and bonding strength

Water. Handling of solvent

Suggestions in 10 ℃

Degree.

With the appropriate measures.

(50 ° F) the following

OK, because the adhesive will change

Too hard and not sticky

Paste. Nevertheless, such as

Correct use, low temperature

The holding force can also be

Satisfactory effect.

Product description:

The column value is decided by the standard test method, and is the mean value, not as a standard specification purposes. Recommendations based oncr

edible we test the use of our products, but we ask your own test to determine the suitability of products for your purposes.

Important notes:

Please customers prior to the use of small batch trial, such as quality problems immediately stopped, and inform the technician of our company.

Compensation and liability limits:

The use of the product, we only covering fabric, not liable for joint and several liability arising from the use of materials.

The 2 test report

P65BW and X653-2 black double-sided tape] b]

Colors

.jpg)